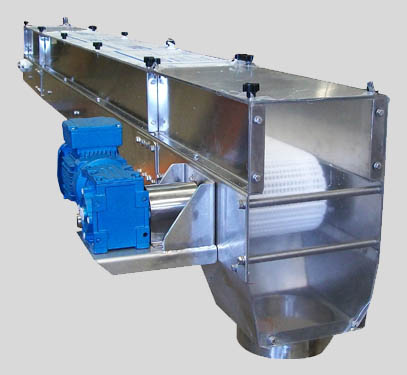

Recently, a client contracted Uni-Pak Corp. to design and custom build a cap conveyor used to handle 63 mm flat caps within a food industry application. Performing a variety of fabrication services, including bending, cutting, grinding, and machining, we manufactured this unit to meet exact client product requirements.

Constructed from a combination of stainless steel and polycarbonate materials, this conveyor system featured multiple conveyor belts of various sizes to move flat caps from one area of production to another. This cap conveyor system was designed to handle up to 300 caps per minute. We manufactured all of the unit’s various components, ranging from the 11-Ga SS base frame to the 6″ deep SS guide rails, the integrated end chutes and receivers, and the clear polycarbonate top covers.

After the unit was manufactured, we tested the cap conveyor using our client’s products. Once assured that the depalletizer met all of our customer’s project specifications, we then shipped the finished cap conveyor to our buyer’s facility within a short, 4-week turnaround time.