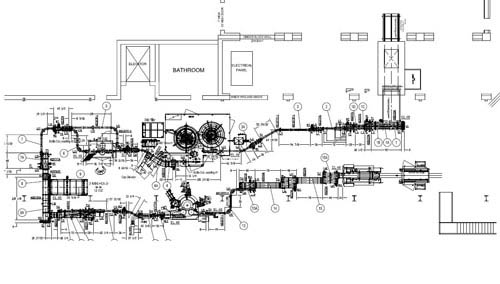

This custom built bottle handling system was fabricated for a Micro-Brewery customer who wanted to increase their filling speed and reduce labor cost. As the system integrator for the project, Uni-Pak Corp. was responsible for the integration of all the equipment on the line. Included with the conveyor system we also provided a floor level depalletizer, a rinser, and a bi-directional accumulating table. Installation supervision was provided during the entire project.

The finished system was able to process 12oz. glass at 300 bottles per minute (PBM), 22oz. glass at 200 BPM, and 750ml glass at 75 BPM.

For more information on this product, or to find out what Uni-Pak can build for you, see the table below or contact Uni-Pak directly.